Chasing and Repousse tools, although very low tech, require basic parameters to perform well. Tons of people ask me what tools they need, which shapes and sizes etc. To me it is important FIRST, to know the basics of what makes a good chasing tool.

A Length of 4″or so is  good for most hands. The shanks should be squared (at least somewhat) so you know which way your chasing tool is facing in your fingers. Completely round stock sort of rolls around in your fingers and I prefer them mainly for round nosed tools like beading tools.

good for most hands. The shanks should be squared (at least somewhat) so you know which way your chasing tool is facing in your fingers. Completely round stock sort of rolls around in your fingers and I prefer them mainly for round nosed tools like beading tools.

The corners of the shank should be soft and comfortable to hold. They should not be sharp, bent or deformed in any way. There should be some length to the taper to the tool face for good line of sight. The faces should be satin smooth or polished shiny. Nothing should be left sharp.

The striking end should be left annealed and the working face hardened and tempered to about an inch back. The old machinists’ handbooks teach that the hammer for the punch is to be hardened to prevent a hollow from developing in the face. Hard steel on hard steel is risky. Slight mushrooming on the striking end of a punch can easily be dressed with a file when needed.

Punches suffer concussive blows with cracking force. For this reason they are traditionally made from solid rolled steel, cut to length and ground or forged into shape. Rolled steel has a long strong crystal structure that resists cracking when correctly heat treated.

That said, I have come across lots of tools missing all or several of these basics. But now you have a guide to help you decide for yourself.

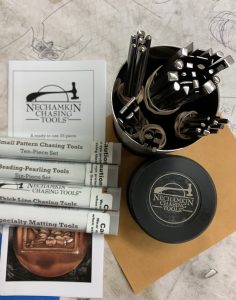

All Nechamkin Chasing Tools are made using these parameters. I personally oversee the quality. Every tool has my family name on it.https://nechamkin.com/chasing-tools/